Here are a few examples where our design team found optimal solutions to meet the client's needs.

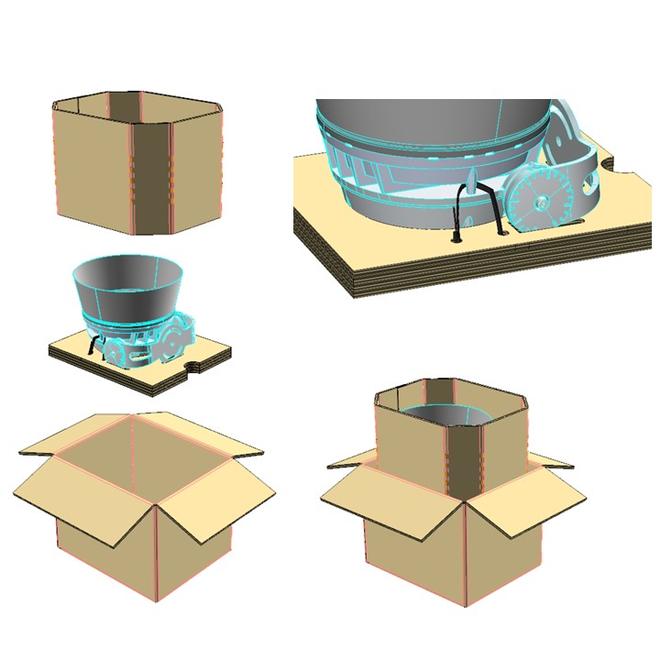

Luminaire Packaging

Challenge: The client required a single recyclable packaging solution without any support on the sides or top of the luminaire due to several physical constraints of the product.

Solution: We proposed securing the luminaire with two 'tie-wrap' attachments passing through the cardboard base. An octagonal sleeve is then placed over this base to secure it in case the box overturns. This method completely immobilizes the product without the need for support in different areas.

Benefits: This concept allows for adapting a single packaging solution to a wide range of products. It's 100% recyclable, and the octagonal sleeve enables increased stacking without risking damage to the delicate part of the luminaire.

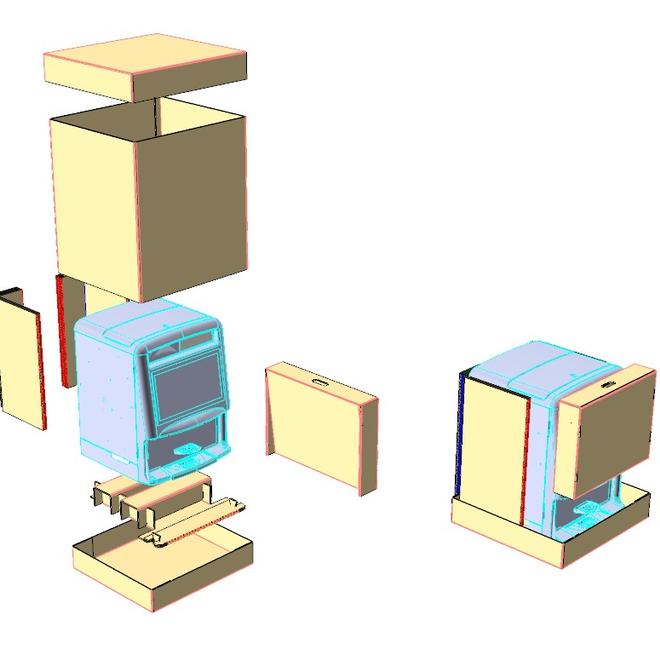

Coffee Dispenser Packaging

Challenge: The client sought a 100% recyclable solution for packaging their coffee dispenser. Due to its considerable weight, the packaging needed to elevate the product to prevent pressure on its legs.

Solution: The entire solution relies on the rigid structure of the base. This structure is robust enough to support the product and is easy for the client to assemble. Triple-walled cardboard corners and an angled accessory box that conforms to the front of the device complete the stabilization of the product within its box.

Benefits: The client not only received a completely recyclable packaging solution but also found it to be less expensive than their previous packaging. Additionally, the components arriving flat on pallets take up significantly less space in their warehouse.

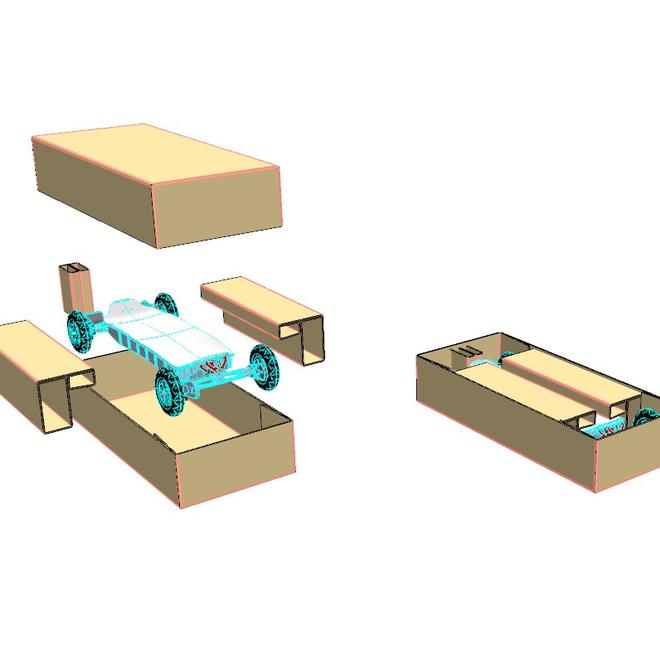

Skateboard Packaging

Challenge: The client required a protective, minimalist, and recyclable packaging solution for their electric skateboard, which is heavy due to the battery weight.

Solution: We suggested using a tray with a cover to reinforce the sides. By adding cardboard rolls, we achieved complete immobilization of the skateboard within the packaging.

Benefits: The client was impressed by the simplicity of assembly and the cost-effectiveness of the packaging solution.

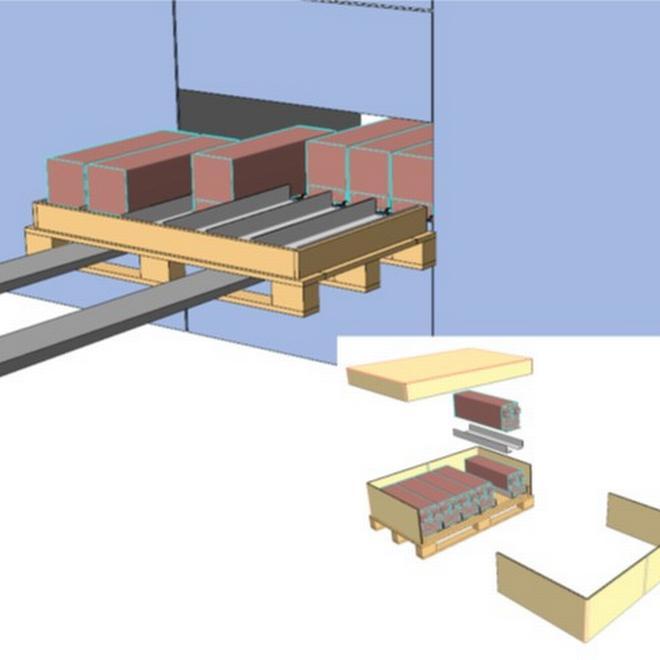

Shipping Batteries for Transportation Industry

Challenge: A manufacturer of batteries for electric buses sought a solution to ship battery sets to Europe and directly install them in vehicles without manual handling.

Solution: We proposed a wooden pallet aligned with the vehicle's battery compartments. Using a rail system made of silicone-laminated angles, the client could simply push the battery into place by hand without lifting it.

Benefits: The client was able to reduce installation time and the risk of injuries since employees no longer had to lift heavy batteries.

Skip site navigation

Skip site navigation